When you start shopping for a travel trailer, you’ll learn that there are two basic types of construction to consider. Each has advantages, and each has a history of satisfying countless trailer campers over many years. That said, what are the key differences and advantages? And as someone looking for a travel trailer, which is the right choice for you?

The basic differences

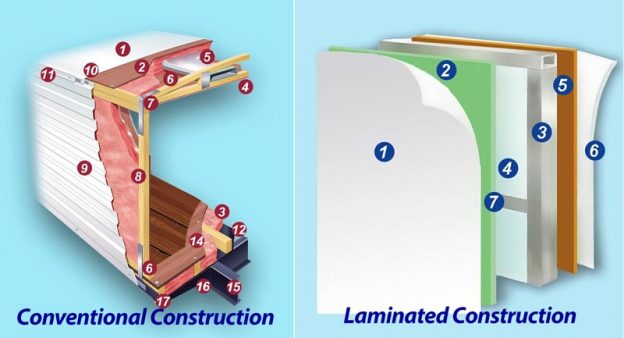

Conventional construction (here are some examples) is the tried-and-true industry standard since the first mass-produced travel trailers. It uses construction features adapted from residential construction. Walls have upright wood studs 13″ to 16″ on center. Floors have wooden joists, and ceilings have wooden rafters. Aluminum siding covers exterior walls and wall insulation is familiar spun fiberglass. Inside walls are rigid panels covered with vinyl. Instead of shingles, a seamless synthetic membrane covers the roof, and an electroplated steel frame replaces a traditional foundation.

Laminated construction (here are examples) builds a skeleton of welded square-tube aluminum instead of wood studs. Instead of spun fiberglass, closed-cell rigid foam insulation fills the frame, and exterior walls are sheets of fiberglass. Laminated construction uses robotically applied glues to join all the layers of the wall. A vacuum chamber then bonds the layers together into a single solid panel.

Conventional construction has the key advantages of being less expensive, simpler, and easier to repair.

The big advantages of laminated construction are its light weight, stiffness, and easy cleanup.

Keep exploring – You’ll be an expert soon

Of course, there are variations on the basics described above, and much more to the story of both methods. You can find diagrams and explanations of our construction right here on the Gulf Stream Web Site. Here’s a good starting point for more information.